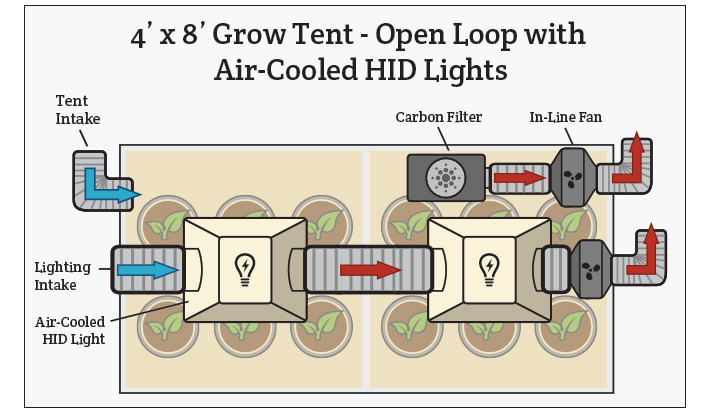

Of course among the most effective choices are to upgrade to lights that emit the least amount of heat like leds or use air or water cooled reflectors.

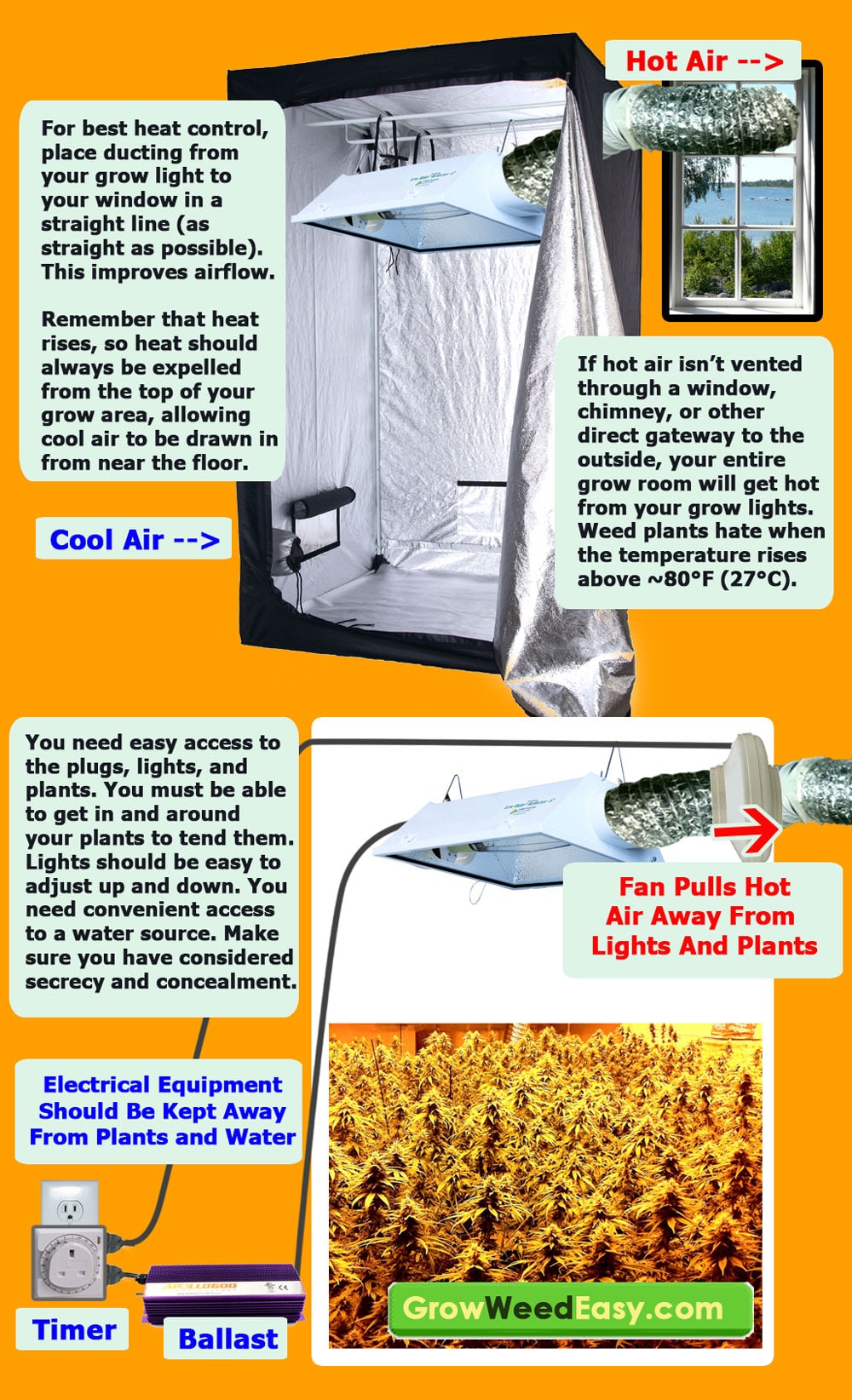

Water cooled lights grow room.

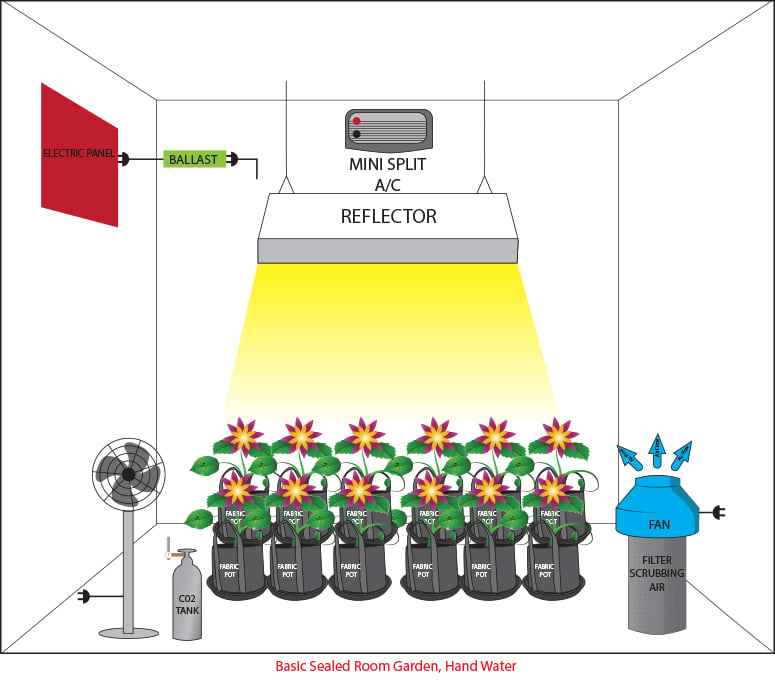

Cooling heating dehumidification ballasts fuse box etc set up.

Al the equipment will be on top of the sealing.

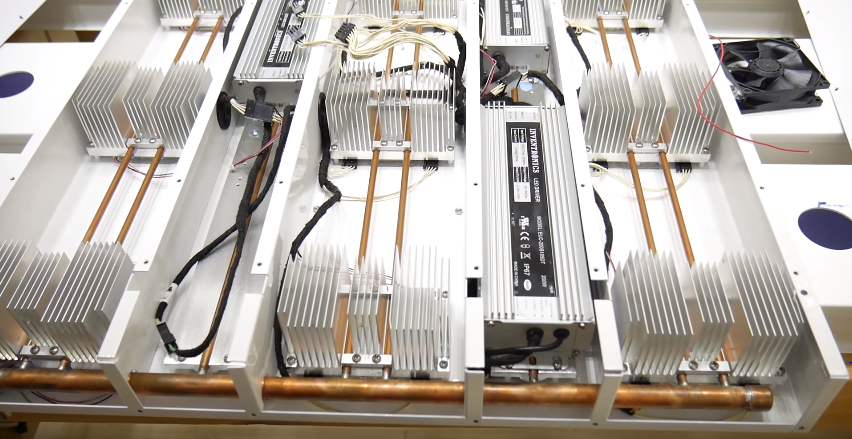

Water cooled lights are a bit more complicated.

The agnetix a3 platform significantly drives down operational costs with its unique water cooling and heat recovery system.

Piped out of the room the heat can be rejected or easily reused to warm the rest of the facility.

Be it your lights a co2 burner air handlers dehumidifier etc 8230.

Chillers are the essential elements of any water cooled grow room setup.

The coolstack is a state of the art high precision led grow light for top lighting applications in greenhouses and grow rooms.

Climate control opticlimate 10000pro2 watercooled climate control unit lights 14x dimlux 400volt 600watt ballasts with philips greenpower 400volt el bulb.

This removes heat from the lighting fixture and removes excess heat from your hydroponics grow room as well.

The chiller is used to cool the water that is passing through the equipment in your grow room.

See more at https tripzero io argriculture water cooling grow leds music used.

Chillers come in a range of sizes and functionalities.

With a market leading output of 1 950µmol s it is the ideal led grow light alternative for hps son t lamps.

You can utilize open or closed systems with individual reflectors or create a series or chain of reflectors allowing one fan to cool multiple lighting fixtures.